Today we offered our 4th workshop in partnership with Tum-A-Lum Lumber. This time we made bat houses for Halloween on a beautiful fall day! Attendees were a mix of regulars and new faces which was great. See photos below and stay tuned for a DIY How-To Guide coming out this winter!

A few notes on building a successful bat house...

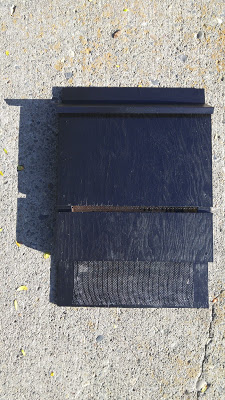

Size: 14" wide by 24" tall is the recommended minimum, depth can vary depending on number of chambers and size of bats that will use the house. The one we built has a single chamber.

Design: Must have an exposed landing pad at the bottom, 3"-6" tall is recommended. Both interior surfaces should be rough so they have something to grab onto. We used wire mesh for this. All seams should be sealed with caulk, especially the roof in order to trap the heat generated by the sun and body heat from the bats. Dark paint is recommended to help absorb heat.

Placement: 15'-20' off of the ground on a pole or south facing building to take advantage of the sun's direct path. Trees should be avoided because they harbor predators and may shade the house.

Check out these links for more information about bats!